A misplaced shipment; A stock report that doesn’t match the actual inventory; Hours wasted scanning barcodes and searching for missing items. These problems are all too common in warehouses. The bigger the operation, the harder it becomes to track everything manually.

RFID (Radio Frequency Identification) is changing the game. Unlike barcodes, RFID tags don’t need direct scanning. They communicate wirelessly, updating inventory systems in real-time. This means fewer errors, faster processing, and better control over stock levels.

But how exactly does RFID work? And why is it a must-have for modern warehouses? Let’s dive in.

How RFID Works in Warehouse Operations

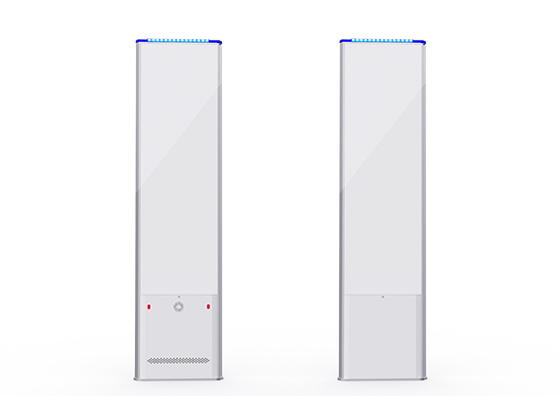

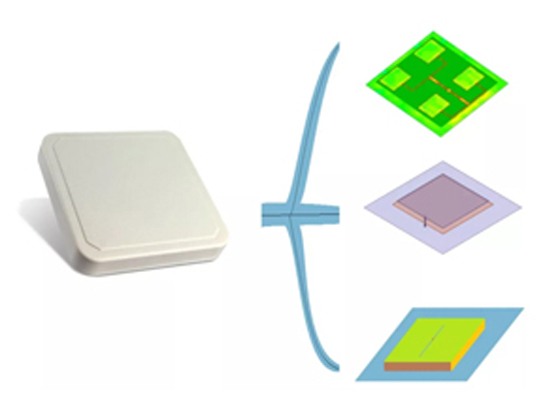

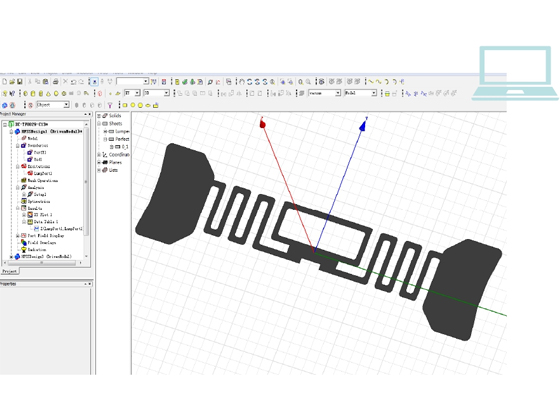

RFID uses radio waves to identify and track items automatically. Each product, pallet, or storage bin has an RFID tag embedded with a unique ID. Readers placed around the warehouse pick up these signals, updating inventory records instantly.

This system eliminates the need for manual scanning. If a shipment arrives, RFID readers detect and log every item without workers having to lift a scanner. When a product moves from one shelf to another, the system updates its location in real time.

Unlike barcode scanners, which require direct visibility, RFID works even if tags are hidden inside boxes or pallets. This makes it much more efficient for large-scale warehouse operations.

Eliminating Errors and Improving Inventory Accuracy

Stock mismatches and lost inventory cost businesses millions each year. Traditional tracking methods rely on human input, which increases the chances of mistakes. RFID removes that risk.

With real-time updates, warehouses always have an accurate count of available stock. If a product is misplaced, RFID helps locate it instantly. This reduces stockouts, over-ordering, and costly manual recounts.

Beyond tracking, RFID enhances security. If an item moves out of a designated area without authorization, the system triggers an alert. This helps prevent theft and accidental loss.

Boosting Warehouse Efficiency with RFID

Speed matters in warehouse operations. When every second counts, scanning individual barcodes is too slow. RFID speeds up key processes, allowing warehouses to handle more shipments with the same workforce.

Receiving becomes nearly effortless—items are logged the moment they pass through RFID checkpoints. Picking and packing are faster because workers can confirm selections without manually scanning each item. Outbound shipments get verified in seconds, reducing errors and improving customer satisfaction.

With RFID, warehouses run leaner, smarter, and more efficiently.

Seamless Integration with Warehouse Management Systems

Technology is useless if it doesn’t work with existing systems. RFID isn’t a standalone solution—it thrives when integrated with Warehouse Management Systems (WMS). A strong WMS combined with RFID creates a self-correcting ecosystem. No more manual stock checks. No more guesswork.

Imagine a warehouse where every item reports its location automatically. Orders update in real time, and replenishments trigger without human input. RFID makes this possible by feeding live data into the WMS. That data then connects with enterprise resource planning (ERP) systems, giving business leaders full visibility into supply chain movements.

For companies aiming to reduce inefficiencies, RFID isn’t just an upgrade—it’s an operational shift. Solutions like BOWEI provides the tools needed to bridge the gap between physical inventory and digital tracking.

Challenges That Come with RFID Adoption

RFID solves many problems, but it’s not plug-and-play. High upfront costs scare off smaller businesses. Some warehouses struggle with interference—metal shelves, liquid containers, and signal congestion can disrupt performance. And integration? That’s where many companies hesitate.

Switching to RFID requires planning. Choosing the wrong tags or poorly placing readers can turn a promising investment into a logistical mess. Warehouses that succeed with RFID invest in expert consultation, site assessments, and phased rollouts. They understand that RFID is an infrastructure shift, not just a tool.

Despite the challenges, those who implement RFID correctly see significant returns. Inventory accuracy jumps. Labor costs drop. Errors become rare. Companies that hesitate risk falling behind as competitors adopt RFID-driven efficiency.

Why RFID Is the Future of Warehousing

Warehouses will only get bigger. Supply chains will only get faster. The question isn’t whether RFID is worth it—it’s whether businesses can afford to operate without it.

RFID isn’t just about tracking inventory. It’s about building a system that works with minimal human intervention. It’s about creating warehouses where products move seamlessly, data updates instantly, and errors become irrelevant.

Companies that invest in RFID today are preparing for a future where manual processes no longer exist. Those that don’t? They’ll be stuck playing catch-up in an industry that rewards efficiency. The choice is clear.

RFID in Action: A Warehouse Without Bottlenecks

Picture a high-volume distribution center. Shipments arrive non-stop, and thousands of items move in and out daily. In a traditional setup, workers scan barcodes one by one, and errors pile up. A single mistake leads to misplaced stock, late deliveries, and frustrated customers.

Now, swap that with an RFID-enabled warehouse. The moment goods enter, RFID readers pick up every tag—logging each item automatically. No manual scanning, no bottlenecks. Inventory updates itself. Workers know exactly where each product is without searching. Orders get fulfilled faster, with fewer mistakes. Customers get their shipments on time, every time.

This isn’t a futuristic concept. It’s happening now. Retail giants, e-commerce warehouses, and logistics companies are already seeing the impact. The ones still relying on outdated tracking methods? They’re losing time, money, and competitive edge.

Who Benefits the Most from RFID?

Not every business needs RFID, but those dealing with high inventory turnover do. Large-scale warehouses, third-party logistics (3PL) providers, and e-commerce fulfillment centers gain the most. When speed and accuracy drive profits, RFID is a necessity.

But even mid-sized operations can benefit. Warehouses handling fragile, high-value, or perishable goods see fewer losses. Automotive and electronics industries use RFID to track components in real-time, reducing misplaced parts. Retail chains rely on it to manage stock across multiple locations.

The reality is simple: if inventory management affects your bottom line, RFID isn’t a luxury—it’s an investment in efficiency. Those who delay adoption risk being outpaced by faster-moving competitors.

Final Thought: RFID Is a Competitive Advantage, Not Just a Tool

Most warehouses operate on outdated methods because "that’s how it’s always been done." But the industry is changing. Businesses embracing RFID aren’t just improving efficiency—they’re redefining how logistics works.

The goal isn’t just tracking inventory. It’s about eliminating friction. A warehouse where data updates itself, shipments move without delays, and errors don’t happen is no longer a theory. It’s the new standard.

Companies that hesitate will find themselves outperformed by those that don’t. The choice isn’t about adopting RFID. The choice is about staying relevant in an industry that’s evolving fast. Warehouse operations that integrate RFID today will set the benchmark for efficiency tomorrow.