In modern logistics warehousing management, efficiency and accuracy are the key factors of enterprise competitiveness. However, the traditional warehouse management is often faced with many challenges, such as difficulty in finding goods, inventory update is not timely and other problems, these problems not only consume a lot of time and manpower, but also may lead to an increase in operating costs. This article will use a real case to describe the application of RFID (Radio Frequency Identification) technology in warehouse management, and how it can help enterprises solve the pain points of traditional warehouse management.

1. Case background

A large logistics company has a warehouse covering tens of thousands of square meters, storing tens of thousands of goods. The daily operation of the warehouse relies on a large number of warehouse keepers and traditional warehouse management tools such as paper records, bar code scanning, etc. However, due to the large scale of the warehouse and the wide variety of goods, warehouse managers often encounter difficulties in finding goods in their daily work.

One day, the company received an urgent order and needed to find a specific box of goods quickly. However, the warehouse keeper conducted a long search inside the warehouse, ransacking the entire warehouse, and took three full days to finally find the box of goods. This incident not only led to the delay of the order, but also consumed a lot of time and manpower, which brought no small loss to the company.

This incident made the company realize that the traditional storage management method has been unable to meet the needs of modern storage management, and must find a more efficient and accurate storage management method. Therefore, the company decided to introduce RFID technology to improve the efficiency and accuracy of warehouse management.

Second, RFID technology introduction

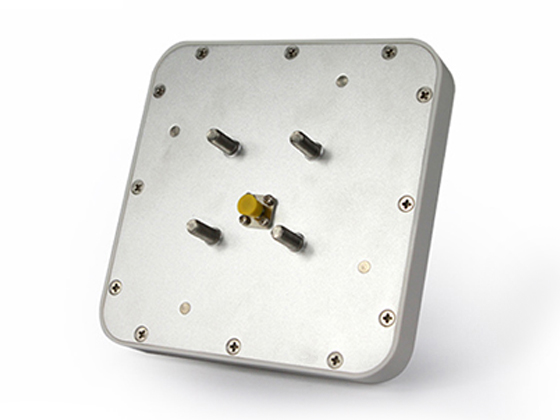

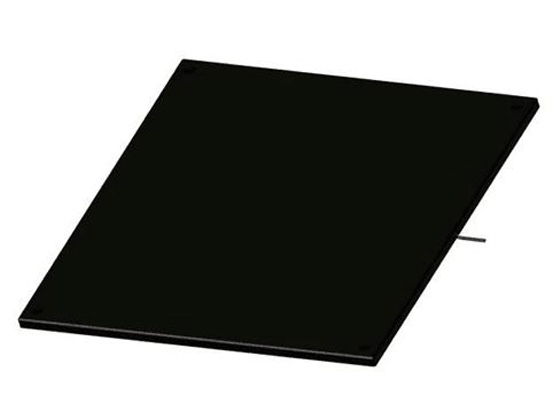

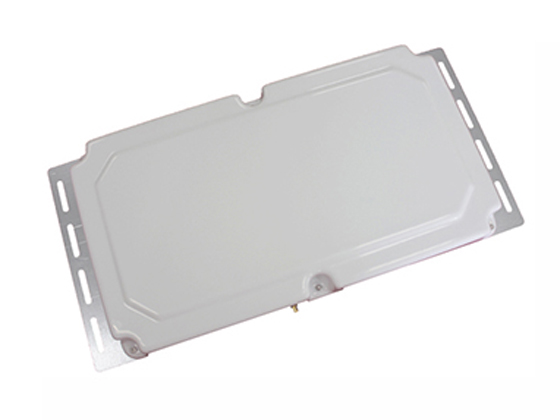

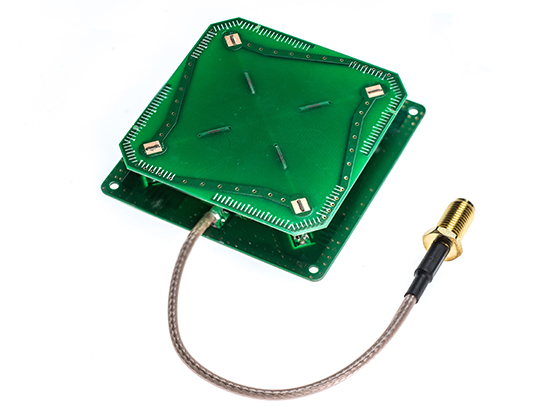

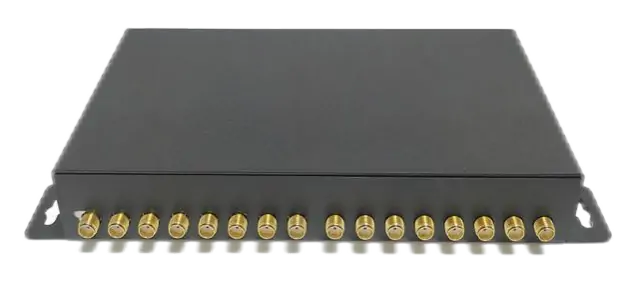

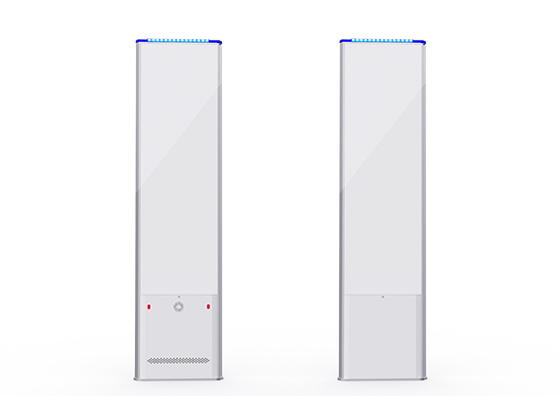

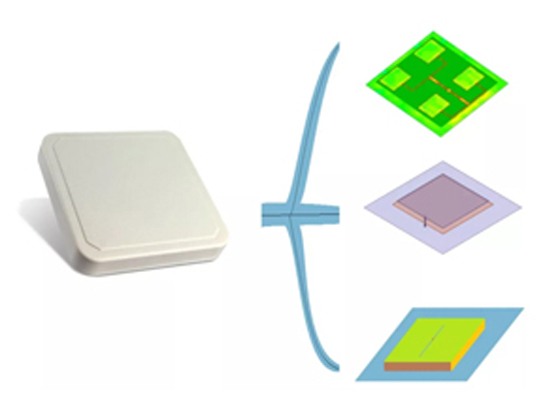

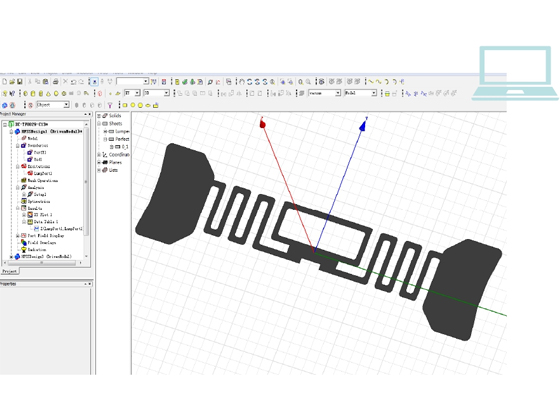

RFID technology is a wireless communication technology, which uses radio frequency signals and spatial coupling (inductive or electromagnetic coupling) transmission characteristics to achieve the automatic identification of stationary or moving items. RFID systems are usually composed of three parts: Tag, Reader and Antenna. The label is attached to the object to be identified and stores the relevant information of the object. The reader sends an RF signal through the antenna to activate the tag and read the information in the tag; The antenna is responsible for transmitting the RF signal between the tag and the reader.

Compared with the traditional bar code technology, RFID technology has many advantages. First of all, RFID tags can store more information, such as the serial number of the goods, production date, shelf life, etc., which can be obtained at the same time when reading, improving the integrity of the information. Secondly, RFID tags can be automatically identified by readers within a certain range, without scanning one by one like bar codes, which greatly improves the identification efficiency. Finally, RFID tags have the characteristics of anti-pollution and wear resistance, and are suitable for a variety of harsh environments.

Third, the application of RFID technology in warehouse management

1. Warehouse management of goods

When the goods are stored, the warehouse manager can attach the RFID tag to the goods, and input the information of the goods into the warehouse management system through the reader and antenna. In this way, the system can update the inventory information in real time to ensure the accuracy of the inventory data. At the same time, due to the uniqueness of the RFID tag, the system can also record the storage location of the goods to facilitate subsequent lookup.

2. Goods search and delivery management

When searching for goods, the warehouse manager can find the target goods in a few minutes by simply scanning inside the warehouse with a handheld RFID reader. This is because the RFID reader can automatically identify multiple RFID tags within a certain range, and the read information is transmitted to the warehouse management system, and the system determines the location of the goods according to the read information. This method not only greatly improves the search efficiency, but also reduces the manpower consumption.

When the goods are out of the warehouse, the warehouse manager can also read the information of the goods through the RFID handheld reader, and compare the information with the order information to ensure the accuracy of the goods. At the same time, the system can also update the inventory information automatically to ensure the real-time of the inventory data.

3. Inventory management

Traditional inventory counting requires warehouse administrators to scan the barcodes of goods one by one and manually input them into the warehouse management system, which is time-consuming and error-prone. After the introduction of RFID technology, the warehouse manager only needs to scan in the warehouse through a handheld RFID reader, and can read the information of multiple RFID tags at one time, and the information is automatically transmitted to the warehouse management system. The system then automatically generates the inventory report according to the information read, which greatly improves the efficiency and accuracy of inventory.

4. Tracking and tracing of goods

Since RFID tags can store the details of the goods, such as serial number, production date, shelf life, etc., RFID technology can also be used for tracking and tracing of goods. Once there is a problem with the goods, such as quality problems, loss, etc., enterprises can quickly locate the problem goods through RFID technology, and trace their source and direction of flow, in order to take timely measures to solve the problem.

Fourth, the effect analysis after the introduction of RFID technology

1. Efficiency improvement: After the introduction of RFID technology, the warehouse manager's cargo finding efficiency has been significantly improved. From three days before to find a box of goods, to now a few minutes can be done, greatly improving the operational efficiency of the warehouse. At the same time, because RFID technology can automatically identify multiple tags, it also greatly improves the efficiency of inventory counting and outgoing warehouse management.

2, cost reduction: After the introduction of RFID technology, enterprises can reduce the dependence on warehouse managers and reduce labor costs. At the same time, because RFID technology can greatly improve the accuracy and efficiency of warehouse management, it can also reduce the increase in operating costs caused by problems such as difficulties in finding goods and timely inventory updates.

3, customer satisfaction: After the introduction of RFID technology, enterprises can more accurately grasp the inventory situation, timely response to customer order needs. At the same time, because RFID technology can greatly improve the efficiency of finding and discharging goods, it can also shorten the delivery cycle of orders and improve customer satisfaction.

4, decision support: RFID technology can also provide enterprises with more comprehensive and accurate warehousing management data, such as goods inventory, goods flow, etc. These data can provide strong support for enterprise decision-making, help enterprises optimize warehouse management processes and improve operational efficiency.

By introducing RFID technology, a large logistics company successfully solved the pain points in traditional warehouse management and improved the efficiency and accuracy of warehouse management. In the future, with the continuous development of Internet of Things technology, RFID technology will play a more important role in warehouse management. For example, by combining RFID technology with sensors, cloud computing and other technologies, more intelligent warehouse management can be achieved. By combining RFID technology with big data analysis, inventory demand can be predicted more accurately and inventory structure can be optimized.